Real Fruit Power

Réal, the No. 1 Juices and Nectar Brand in India, has provided fruit nutrition to millions of consumers for over two decades. With Réal, comes the guarantee of best quality fruits, to ensure refreshing taste and fruit goodness and it is this consistent quality which has made Réal the most trusted brand in the category for over a decade.

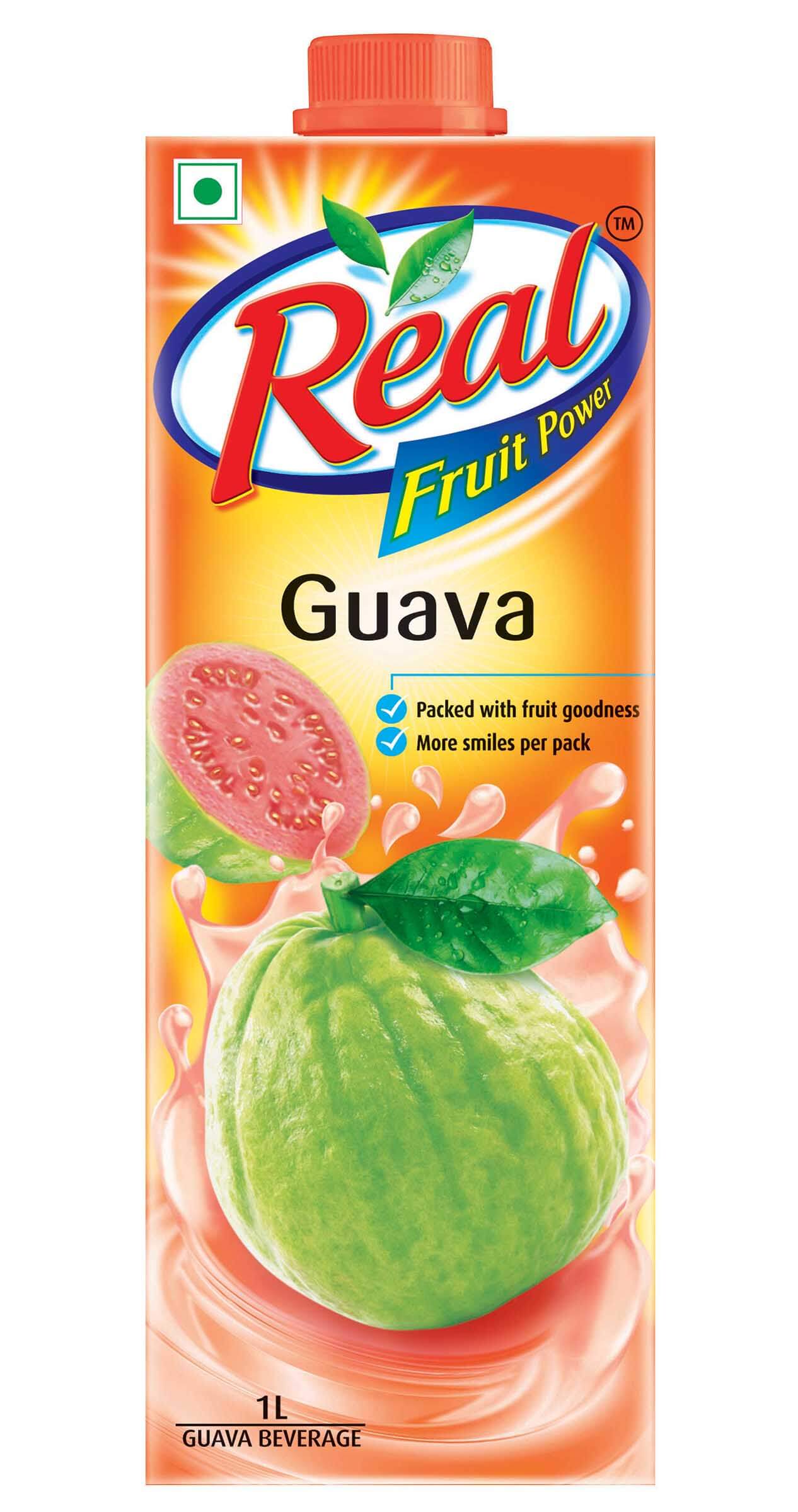

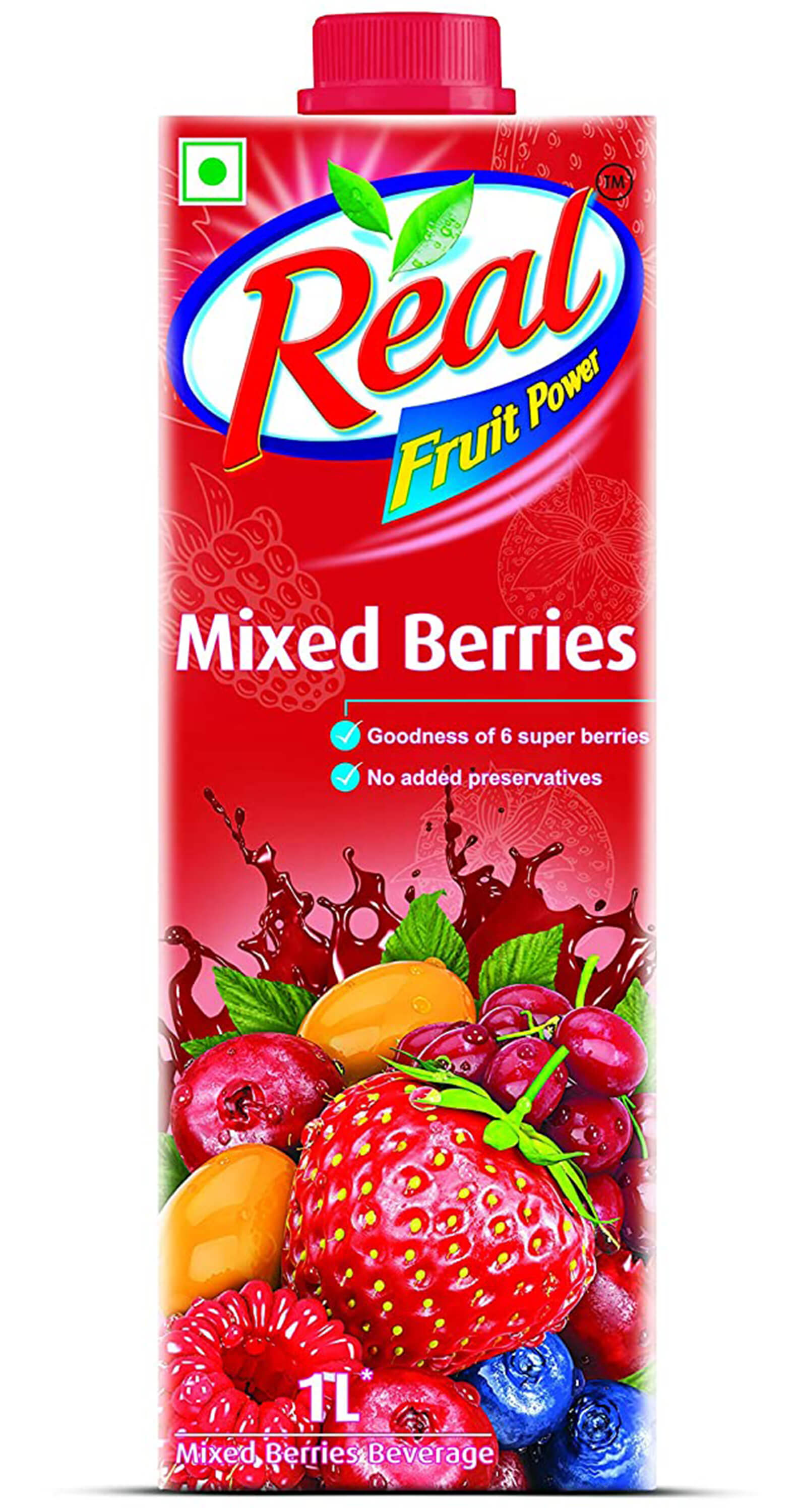

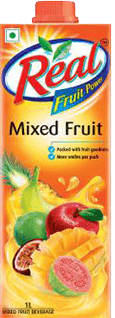

Explore the brand’s product portfolio

Brand offerings

Health Benefits

Powerhouse of Antioxidant

Rich in Vitamin C

Helps Boost immunity

Usage

Consume within 5 days of opening the pack

Keep away from direct sunlight

Do not buy if the pack is puffed / leaked/ or seal is broken

User Guide

How to Use

Shake well and serve chilled

Shake Well Before Use

Refrigerate after opening the pack

Tastes best when served chilled

Usage

Consume within 5 days of opening the pack

Keep away from direct sunlight

Do not buy if the pack is puffed / leaked/ or seal is broken

Our stories

Rich in Vitamin C that helps boost Immunity

Réal, the No. 1 Juices and Nectar Brand in India, has provided fruit nutrition to millions of consumers for over two decades. With Réal, comes the guarantee of best quality fruits, to ensure refreshing taste and fruit goodness and it is this consistent quality which has made Réal the most trusted brand in the category for over a decade.