Manufactured Capital

Dabur is today one of the most diversified players in the FMCG sector, with a product portfolio that encompasses traditional Ayurvedic products to mainstream FMCG categories such as hair oils, toothpastes, shampoos, and beverages in multiple pack sizes and formats. This breadth has required us to build a highly agile and resilient manufacturing network across nine countries — India, the UAE, Nepal, Bangladesh, Sri Lanka, South Africa, Nigeria, Egypt, and Turkey — ensuring that Dabur’s popular brands and products reach consumers in over 120 countries.

In FY 2024-25, Dabur took a significant step in expanding its domestic manufacturing footprint by signing a facilitation Memorandum of Understanding (MoU) with the Government of Tamil Nadu to establish its first manufacturing facility in South India. Located in SIPCOT Tindivanam providing quick connectivity to key marketplaces in South, this state-of-the-art, multi-category unit is designed to be one of Dabur’s most modern and environmentally responsible facilities. The Phase 1 investment of ₹135 Crore is expected to scale up to ₹400 Crore over five years, generating direct employment for around 250 people and thousands of indirect jobs.

Strategically positioned to serve the growing demand in South India, the facility will initially manufacture products such as Dabur Honey, Red Toothpaste, and Odonil Air Freshener, with plans to diversify its portfolio in subsequent phases. The site will also source raw and packaging materials from the local market benefiting the local vendor base and farmers.

All Dabur manufacturing locations continue to embrace a culture of continuous improvement through the “Kaizen” mindset. This innovation-driven mindset, coupled with investments in advanced manufacturing technologies and sustainability practices — including energy-efficient construction and effluent treatment systems — positions Dabur’s manufacturing ecosystem as agile, future-ready, and environmentally conscious.

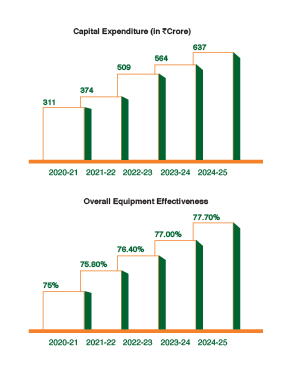

Key Highlights of FY 2024-25

70 bps

Improvement in OEE in FY 2024-25 to 77.7%

414.87

Crore Capex (Standalone) and ₹ 636.95 Crore Capex (Consolidated) incurred in FY 2024-25

26

C & F Agents

4

Mother Warehouses across India

8

Bioresources Development farms

At Dabur, environmental stewardship is not just a responsibility—it is a strategic imperative. As part of our commitment to sustainable growth, we have embedded energy conservation and climate-conscious practices into the core of our operations. Our focus remains on reducing reliance on non-renewable energy sources, enhancing energy productivity, and lowering our environmental footprint, all while maintaining operational excellence.

Despite the energy-intensive nature of our manufacturing processes, particularly in the beverage business, we have achieved a 12% reduction in Energy Intensity from our baseline. This milestone reflects our unwavering commitment to greening our operations and transitioning toward a low-carbon future.

Key initiatives undertaken in FY 2024–25 include:

- Adoption of high-efficiency technologies: We have deployed IE3/IE4 energy-efficient motors and upgraded process equipment across our facilities to reduce energy draw without compromising performance.

- Smart energy controls: Installation of LED lighting and Variable Frequency Drives (VFDs) has enabled us to optimise energy usage dynamically across operations.

- Compressed air optimisation: Through pressure-based VFD controls, improved piping layouts, and proactive leakage management, we have significantly reduced energy losses in our compressed air systems.

- Sustainable thermal energy: Our biomass-based boilers, integrated with waste heat recovery systems such as Air Preheaters (APH) and Economisers, have helped cut down fossil fuel consumption.

- Digitally enabled efficiency: We have implemented IoT- and AI-driven monitoring systems for our boilers, enabling parameter-based operations and real-time energy optimisation.

- Condensate recovery systems: These have been strengthened to reclaim thermal energy, further improving overall plant efficiency.

Capital Investments for Green Operations

| S.no. | Steps Taken on Energy Efficiency | Capital Investment (in Lakhs) |

| 1. | Use of Energy-Efficient Motors (IE3/IE4) & Devices | 350 |

| 2. | Optimised use of Energy using VFDs & LED Lights | 362 |

| 3. | Energy efficiencies in Boiler using heat recovery through APH. Economisers etc. | 171 |

| 4. | Digitisation of Utilities, Use of Energy monitoring systems/SCADA based Utilities monitoring. Online monitoring and controlling of parameters benefitting in reduced fuel consumption in Boiler | 37 |

| 5. | Condensate recovery systems with pumps towards energy savings and reduced water consumption | 16 |

| Total Investment | 936 |

Accelerating the Shift to Green Energy

As part of our long-term commitment to environmental stewardship, Dabur continues to prioritise the transition to green energy across its operations. This strategic focus is central to our efforts to reduce Scope 1 and Scope 2 emissions and build a more sustainable, low-carbon business.

These initiatives are aligned with Dabur’s broader ambition to become a Net Zero Emissions Enterprise by 2045 — a goal we are advancing through decisive action and measurable outcomes. Notably, we have already eliminated coal from our operations. In FY 2024–25, Dabur achieved a significant milestone by increasing the share of renewable energy in its Scope 1 and 2 energy consumption by 1,000 basis points. As a result, 61% of our total energy consumption was sourced from renewable energy — a target we reached 12 months ahead of our publicly stated FY 2025–26 goal.

Key highlights of our green energy transition include:

- Corporate Office Powered by Solar: Our corporate headquarters in Ghaziabad, Uttar Pradesh, now operates 100% on renewable electricity, setting a benchmark for sustainable office infrastructure.

- First 100% Solar-Powered Factory: The Sahibabad manufacturing facility became the first in the Dabur network to run entirely on renewable electricity, reinforcing our commitment to clean energy adoption at scale.

| S.no. | Steps taken on Energy Sustainability | Capital Investment (in Lakhs) |

| 1. | New Captive Rooftop Solar power plant – - 1.2 MW in Baddi & 0.5 MW in Indore | Opex Model |

| 2. | Bio Briquette boilers 12 TPH Indore, 10 TPH Pantnagar & 2 TPH Newai | 2,176 |

| 3. | Open Access Solar Investment for Corporate office (1.5 MW DC) | 39.5 |

A total of ₹31.5 crore was invested during the year in Energy Efficiency and Sustainability initiatives, underscoring our dedication to long-term environmental impact reduction. These initiatives and achievements reflect Dabur’s proactive approach to greening operations. As we move forward, we remain committed to scaling these efforts, fostering a culture of sustainability, and leading by example in the FMCG sector’s transition to a Greener Future.

As part of our commitment to gender equity and inclusive growth, Dabur continued to not just scale its pioneering initiative of establishing an all-women production line at our largest greenfield facility near Indore but also expand it to other units in India. The year 2024-25 saw Dabur pilot similar all-women production lines in three other units – Jammu, Baddi and Silvasa.

This initiative in Indore is dedicated to manufacturing products from our ‘Made for Women, by Women’ portfolio, including flagship brands such as Vatika and Amla Hair Oils. Launched in FY 2023-24 with a team of 20 women operating a single shift, the initiative has been scaled up in FY 2024-25. The all-women team now operates across three shifts and is capable of producing over 2.5 million packs annually with excellent quality, safety, morale and productivity standards.

Beyond its social impact, the initiative has delivered measurable operational benefits. The all-women production lines have demonstrated remarkable gains in productivity:

- Amla Hair Oil (AHO) Line: Productivity improved by 30%, increasing from 30.31 cases/person to ~40 cases/person.

- Vatika Hair Oil (VHO) Line: Productivity surged by 50%, rising from 12 cases/person to 18 cases/person.

These improvements reflect the team’s exceptional efficiency, attention to detail, and commitment to quality. The initiative has also helped break gender stereotypes in a traditionally male-dominated sector, while fostering a culture of safety, collaboration, and empowerment.

Dabur’s all-women production line is not just a symbol of inclusion — it is a model of how diversity can drive operational excellence and sustainable growth.

At Dabur, our supply chain is more than a logistical backbone — it is a strategic enabler of our customer promise. In the fiscal year 2024–25, our logistics network efficiently managed the movement of over 6 lakh tonnage and 57 million cases of finished goods. This extensive operation was supported by a robust infrastructure comprising 4 Mother Warehouses, 26 Carrying & Forwarding Agents (C&FAs), more than 81 third-party manufacturing units, and 12 proprietary manufacturing facilities.

We view our ecosystem of suppliers, channel partners, distributors, and vendors as integral to our collective success. Through close collaboration, we uphold stringent quality, safety, and service standards, ensuring that every product reaches our consumers with the trust and care they expect from Dabur.

In line with our commitment to achieving Net Zero emissions by 2045, Dabur is actively transforming its supply chain to reduce environmental impact. Our logistics decarbonisation strategy is anchored to:

Optimised Route Planning & Higher Loadability

Through strategic route optimisation and the deployment of higher-tonnage vehicles, we achieved a reduction of approximately 150 metric tons of carbon dioxide (CO2) emissions during the fiscal year. The integration of higher-capacity trucks further amplified our sustainability efforts. By maximising load capacity and reducing the number of trips required, this approach aligns with industry best practices, where increasing vehicle fuel efficiency and optimising load factors are recognised strategies for lowering greenhouse gas emissions.

Strategic Modal Shift to Rail/Multimodal Transport

In a significant move towards sustainable logistics, we expanded our utilisation of rail transport, achieving a threefold increase compared to the previous fiscal year. This modal shift from road to rail is a well-established method for reducing carbon emissions, as rail transport is substantially more energy-efficient and emits significantly less CO2 per ton-kilometre than road transport. Our transition to rail logistics resulted in an estimated reduction of approximately 300 metric tons of CO2emissions, underscoring our commitment to environmentally responsible operations.

We view technology as a strategic enabler of innovation, efficiency, and consumer delight. Our commitment to continuous improvement drives us to explore and adopt cutting-edge technologies across our value chain. We actively engage with domain experts, equipment manufacturers (both domestic and global), digital innovators, and startups to co-create solutions that enhance our operational performance and elevate the consumer experience.

In FY 2024–25, our efforts toward technology absorption yielded tangible benefits across product innovation, cost optimisation, import substitution, and process excellence.

Manufacturing & Processing Systems

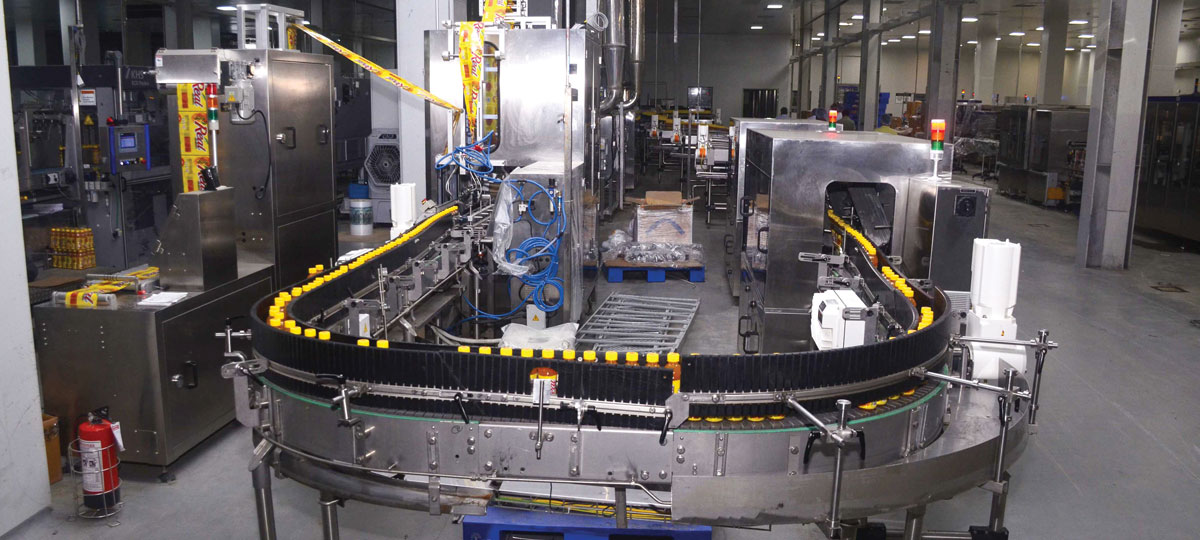

- Ultra-High Temperature (UHT) Sterilisers: Two state-of-the-art UHT steriliser setups were commissioned, significantly enhancing our capacity to deliver innovative beverage formats with extended shelf lives.

- Carbonated Soft Drink (CSD) Line: A new high-speed in-house CSD processing line was installed at our Jammu facility, enabling agile production and faster go-to-market for fizzy beverages.

Primary Product Filling Systems

- Aseptic PET Bottle Line: A first-of-its-kind high-speed aseptic PET filling line was introduced at our Indore plant. Capable of producing pack sizes from 150 ml to 1L, the line features end-to-end automation for enhanced hygiene and efficiency.

- Ultra-High-Speed PET Line: Also at Indore, we commissioned an ultra-high-speed PET filling line with similar pack flexibility and end-to-end automation.

- Carton Filling Innovation: Dabur now operates one of the world’s fastest beverage carton filling lines, capable of packing 40,000 units per hour with no human touch.

End-of-line Automation

- Robotic Palletizers: To manage SKU complexity and improve manpower productivity, robotic palletizers capable of handling four SKUs simultaneously were deployed. At Indore, case packers and palletizers were integrated into high-speed juice lines to streamline operations.

Warehousing & Inventory Management

- SAP WMS Integration: Our Tezpur facility implemented SAP Warehouse Management System (WMS), enabling barcode-based SKU tracking, automated FIFO retrieval, and digitalised inventory control-eliminating manual intervention and enhancing agility.

Digital Transformation

As part of our broader digital journey, Dabur has adopted several next-gen technologies:

- Industrial IoT 4.0 for real-time safety monitoring and asset performance.

- ESG Performance Dashboards & trackers to track sustainability metrics.

- Freight Optimisation Tools to reduce logistics costs and emissions.

- Robotic Process Automation (RPA) to streamline customer service workflows.

- Cloud Migration & Data Lake Implementation to strengthen enterprise-wide analytics and decision-making.

These initiatives reflect our belief that technology is not just a tool, but a mindset—one that empowers us to lead with agility, precision, and purpose in a rapidly evolving marketplace.

A total investment of ₹48 crores was made on imported technologies during the FY 2024-25. Details of imported technology (imported during the last three years reckoned from the beginning of the financial year) are available in the Director’s Report section of this Annual Report.

We are dedicated to achieving operational excellence by building the right capabilities and capacities, and by embracing industry best practices. At Dabur, we regularly organise Kaizen melas across all manufacturing units to boost employee engagement, harness the collective expertise of our workforce, and strengthen their problem-solving abilities.

In the year 2024-25, our employees submitted a total of 2,700 Kaizen projects, and all of them were implemented across domains such as safety, productivity, quality, and morale, resulting in cost savings exceeding ₹ 4.21 Crore.

Dabur’s Manufactured Capital is the backbone of our ability to deliver high-quality, natural and science-backed products to millions of consumers globally. As we continue to scale operations to meet rising demand and evolving consumer preferences, we are focused on transforming our manufacturing infrastructure into a more agile, efficient, and sustainable ecosystem.

Capacity Expansion to Enable Growth

To support our growth ambitions — both domestic and international — we will continue to invest in strategically located, scalable, and modular manufacturing units. These facilities will be built with flexibility, agility & sustainability in mind, enabling us to respond swiftly to a dynamic market shifts and new product introductions. We also plan to strengthen our contract manufacturing network to support faster go-to-market strategies and cost efficiencies.

Digitalisation and Smart Manufacturing

We are advancing towards Industry 4.0 adoption by embedding digital technologies across our manufacturing footprint.

This includes:

- Implementing automation and IoT-enabled production systems for better accuracy, consistency, and real-time monitoring

- Using advanced analytics for predictive maintenance, quality assurance, and yield optimisation

- Digitising supply chain and production workflows for enhanced visibility and faster decision-making

This transition will improve not only productivity but also responsiveness and agility across the value chain.

Sustainable and Responsible Manufacturing

Our future-ready manufacturing approach is deeply aligned with our sustainability goals. We aim to:

- Enhance resource efficiency by reducing energy, water, and material consumption per unit of production

- Transition to renewable energy across key facilities

- Achieve zero waste-to-landfill status at more locations through circular economy practices

- Invest in eco-friendly packaging and process innovation to reduce the environmental footprint

We are also strengthening our environmental monitoring systems to track and report our sustainability performance with greater accuracy and accountability.

Quality and Resilience at the core

Our manufacturing strategy remains anchored in uncompromising quality and operational resilience. Going forward, we will:

- Expand our multi-location manufacturing model to mitigate geographic risk and ensure business continuity

- Build greater raw material security through backward integration and diversified sourcing

- Continue upskilling our plant workforce and embracing digital tools to foster a culture of continuous improvement & zero-defect mindset.

Through these focused interventions, Dabur is creating a future-ready manufacturing backbone that will power our innovation pipeline, enhance our global competitiveness, and ensure we continue to serve consumers with excellence and integrity.